Home>Products & Services>Research & Development>R & D Achievements

Home>Products & Services>Research & Development>R & D Achievements

Products & Services

Products Introduction

Research and Development

Certificate

- Cold-rolled Products

- Wide Heavy Plates

- Hot Strips

- Wire and Rod

- Ultra Thin Cast strip

- Achievements of Process Research and Development

-

Tinplate

Specification:Thickness: 0.18~0.55mm Width: 700~1250mm

Standard:JIS G3303,GBT 2520-2017,YZL501-2020

Application:Tin-plates are widely used for the packaging of food, beverage and industrial goods.

-

Property Indexes

MR-T-2.5CA: HR30T : 55±3;

MR-T-3CA: HR30T : 57±3;

MR-T-3CA-D: HR30T : 57±3;

MR-T-3.5CA: HR30T : 59±3;

MR-T-4CA: HR30T : 61±3;

MR-T-4CA-N:HR30T : 61±3;

MR-T-4CA-Y:HR30T : 61±3;

MR-T-4.5CA: HR30T : 63±3;

MR-T-5CA: HR30T : 65±3;

MR-T-4CA-Y: HR30T : 61±3;

MR-T-4.5CA-A: HR30T : 63±3;

MR-T-5CA-A: HR30T : 65±3;

MR-T-5CA-Z:HR30T为65±3;

MR-T-5CA-Y:HR30T为65±3;

MR-T-5CA-P:HR30T为65±3;

MR-T-4CA-P: HR30T : 61±3;

MR-T-4.5CA-P: HR30T : 63±3;

MR-T-4CA-B: HR30T : 61±3;

MR-T-4.5CA-B: HR30T : 63±3;

MR-T-5CA-B: HR30T : 65±3;

-

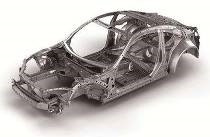

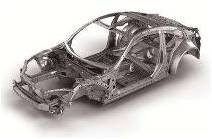

Cold rolled carbon structural automotive steel

Specification:Thickness: 0.6~1.8mm,Width: 750~1300mm

Standard:Q320582 YZL303-2020

Application:Car body,Slide rail

-

Property Indexes

Q235B-L: Rp0.2: ≥235MPa,Rm: ≥375MPa,A80≥28%

HC380LA: Rp0.2: 240-380MPa,Rm: ≥390MPa,A80≥29%

S245G: Rp0.2: 235MPa,Rm: ≥375MPa,A80≥30%

-

Cold rolled low carbon steel

Specification:Thickness: 0.25~2mm Width: 750~1300mm

Standard:GB/T 5213-2019

Application:Building, household electric appliances, steel drum, flux cored wire

-

Property Indexes

DC01: Rp0.2≤300MPa,Rm≥270 Mpa,A80≥30%

DC03: Rp0.2≤260MPa,Rm≥270 MPa,A80≥35%

r90≥1.3

SGYT:Rp0.2≤260MPa,Rm≥270 MPa,A80≥38%

HS1:Rp0.2 160~240MPa,Rm≥270 MPa,A80≥39%

DCK: Rp0.2 180~300MPa,Rm300~390MPa ,A50≥33%

-

Non-oriented silicon steel

Specification:Thickness: 0.20~0.50mm

Standard:Q/320582 YZL601-2022

Application:Small motors, household electric appliances, small transformers and new energy vehicles

-

Property Indexes

SG50WH600:P15/50≤3.6W/Kg, B50≥1.71T

SG50WH470:P15/50≤3.1W/Kg, B50≥1.70T

SG50W1300:P15/50≤6.0W/Kg, B50≥1.74T

SG50W1000:P15/50≤5.4W/Kg, B50≥1.72T

SG50W800:P15/50≤5.0W/Kg, B50≥1.72T

SG50W700:P15/50≤4.6W/Kg, B50≥1.71T

SG50W600:P15/50≤4.2W/Kg, B50≥1.69T

SG50W470:P15/50≤3.6W/Kg, B50≥1.67T

SG50W400:P15/50≤3.0W/Kg, B50≥1.68T

SG50W350:P15/50≤2.8W/Kg, B50≥1.68T

SG35W550:P15/50≤3.6W/Kg, B50≥1.67T

SG35W440:P15/50≤3.1W/Kg, B50≥1.69T

SG35W360:P15/50≤2.8W/Kg, B50≥1.68T

SG35W300:P15/50≤2.7W/Kg, B50≥1.66T

SG35WV2000:P10/400≤19.8W/Kg, B50≥1.65T

SG35WV1900:P10/400≤18.8W/Kg, B50≥1.65T

SG35WV1700:P10/400≤17.0W/Kg, B50≥1.63T

SG30WV1800:P10/400≤18.0W/Kg, B50≥1.62T

SG30WV1500:P10/400≤15.0W/Kg, B50≥1.62T

SG30WHV1500:P10/400≤15.0W/Kg, B50≥1.65T

SG27WV1400:P10/400≤14.0W/Kg, B50≥1.63T

SG27WHV1400:P10/400≤14.0W/Kg, B50≥1.65T

SG25WV1300:P10/400≤13.0W/Kg, B50≥1.62T

SG25WHV1300:P10/400≤13.0W/Kg, B50≥1.65T

SG20WV1300:P10/400≤13.0W/Kg, B50≥1.62T

SG20WV1200:P10/400≤12.0W/Kg, B50≥1.60T

-

Chromium free passivated、Chromium-free fingerprint-resistant hot galvanized plate for appliance (DX51D+Z、DX52D+Z、DX53D+Z)

Specification:Thickness: 0.29~1.4mm, Width: 910~1250mm

Standard:GB/T 2518-2008

Application:Electric Appliance

-

Property Indexes

Satisfying all mechanical properties and surface quality requirements of GB/T 2518-2008 and the customers for DX51D+Z、DX52D+Z and DX53D+Z.

-

Cold rolled high strength low alloy automotive steel

Specification:Thickness: 0.6~1.8mm; Width: 750~1300mm

Standard:EN 10268-2006

Application:Car body

-

Property Indexes

HC340LA:Rp0.2: 340-420MPa,Rm: 410-510MPa,A80≥21%;

HC380LA:Rp0.2: 380-480MPa,Rm: 440-560MPa,A80≥19%。

-

Hot-rolled cold forming steel S315MC~S700MC

Specification:Thickness: 2.0~10.0mm

Standard:BS EN 10149-2:1996

Application:For the Bracket of pump truck, crane arm, container plate, chassis, automobile structure.

-

Property Indexes

Satisfying all mechanical properties and surface quality requirements of BS EN10149-2:1996 and the customers for the hot rolled steel for hot-rolled cold forming steel.

-

High strength cold forming Automobile Structure P.O. Strip SG-QSTE 340、SG-QSTE 380、SG-QSTE 420、SG-QSTE 460、SG-QSTE 500

Specification:Thickness: 1.8~6.0mm Width: 750~1550mm

Standard:SEW 092

Application:For automobile components such as automotive components and wheels which require formability processing performance

-

Property Indexes

The mechanical properties meet the normal hot rolled strip . Besides that, there are no pincher, residual iron oxide, hard spot, roll marks and some other surface defects.

-

Automobile Structure P.O. Strip SG-SAPH370、SG-SAPH400、SG-SAPH440

Specification:Thickness: 1.8~6.0mm Width: 750~1550mm

Standard:JIS G3113 ,JIS G3134,SEW092,BS-EN 10149-2

Application:For automobile components such as automotive components and wheels which require formability processing performance

-

Property Indexes

The mechanical properties meet the normal hot rolled strip . Besides that, there are no pincher, residual iron oxide, hard spot, roll marks and some other surface defects.

-

Cold rolled steel for vitreous enamelling DC01EK, DC03EK and DC05EK

Specification:Thickness: 0.30~3.0mm,Width≥600mm

Standard:GB/T 13790-2008

Application:Enamel steel for daily use or industrial use

-

Property Indexes

Satisfying all mechanical properties and surface quality requirements of GB/T13790-2008 and the customers for the DC01EK, DC03EK and DC05EK

-

Hot galvanized plate for appliance DX51D+Z、DX52D+Z、DX53D+Z

Specification:Thickness: 0.29~1.4mm,Width: 910~1250mm

Standard:GB/T 2518-2008

Application:Electric Appliance

-

Property Indexes

Satisfying all mechanical properties and surface quality requirements of GB/T 2518-2008 and the customers for DX51D+Z、DX52D+Z and DX53D+Z.

-

Cold rolled low, ultra-low carbon steel for car body DC01、DC03、 DC04

Specification:Thickness: 0.6~1.8mm,Width: 750~1300mm

Standard:DIN EN 10130-2007

Application:Car body

-

Property Indexes

DC01: Rp0.2≤280MPa,Rm≥270 MPa,A80≥28%

DC03: Rp0.2≤240MPa,Rm≥270 MPa,A80≥34%,r90≥1.3

DC04: Rp0.2≤210MPa,Rm≥270 MPa,A80≥38%,r90≥1.6

-

Cold rolled low carbon steel DC01、DC03、 SGYT、HS1

Specification:Thickness: 0.25~2mm Width: 750~1300mm

Standard:GB/T 5213-2008,Shagang enterprise standard

Application:Building, household electric appliances, steel drum,flux cored wire

-

Property Indexes

DC01: Rp0.2≤300MPa,Rm≥270 MPa,A80≥30%

DC03: Rp0.2≤260MPa,Rm≥270 MPa,A80≥35%,r90≥1.3

SGYT: Rp0.2≤260MPa,Rm≥270 MPa,A80≥38%

HS1: Rp0.2 160~240MPa,Rm≥270 MPa,A80≥39%

-

Hot Galvanized Plate For Building

Specification:Thickness: 0.29~1.4mm Width: 910~1250mm

Standard:GB/T 2518-2008; ASTM A653-05

Application:Building

-

Property Indexes

Satisfying all mechanical properties and surface quality requirements of GB/T 2518-2008 and the customers for DX51D+Z and DX52D+Z.for S220GD+Z、S250GD+Z、 S280GD+Z、 S320GD+ Z. Satisfying all mechanical properties and surface quality requirements of ASTM A653-05 and the customers for CS Type A、CS Type B、Grade 40.

-

Cold Forming P.O. Strip SG-SPHC、SG-SPHD、SG-SPHE

Specification:Thickness: 1.8~6.0mm Width: 750~1550mm

Standard:JIS G3131

Application:For the manufacture of cold forming parts

-

Property Indexes

The mechanical properties meet the normal hot rolled strip . Besides that, there are no pincher, residual iron oxide, hard spot, roll marks and some other surface defects.

-

SG-SAPH440 Automobile Structure P.O. Strip SG-SAPH440

Specification:Thickness: 1.8~6.0mm Width: 750~1550mm

Standard:JIS G3113 ;JIS G3134

Application:For automobile components such as automotive components and wheels which require formability processing performance

-

Property Indexes

The mechanical properties meet the normal hot rolled strip . Besides that, there are no pincher, residual iron oxide, hard spot, roll marks and some other surface defects.

-

Construction High Strength P.O. Strip SG-SAE1026、SG-SAE1035、 SG-SAE1050

Specification:Thickness: 1.8~6.0mm Width: 750~1550mm

Standard:SAE J403

Application:For high strength building

-

Property Indexes

The mechanical properties meet the normal hot rolled strip . Besides that, there are no pincher, residual iron oxide, hard spot, roll marks and some other surface defects.

-

High strength low alloy steel (Q420、Q460、Q500、Q550、Q690、Grade60、Grade65、Grade70、Grade80、Grade100)

Specification:Thickness:0.8-1.8mm;width:1150-1580mm

Standard:ASTM 1039、T/SSEA 0031-2019

Application:Mainly used in automobile structural parts、shelves and supports, truck bodies etc

-

Property Indexes

Yield strength:460~700MPa, tensile strength:480~750MPa, Elongation meets corresponding standard requirements, and the shape and surface quality of the product can reach a high level.

-

High Carbon Steel (45 、50)

Specification:Thickness:0.8-1.8mm;width:1150-1570mm

Standard:Shagang enterprise standard

Application:Mainly used in tape、hairpin etc

-

Property Indexes

Meet composition、profile、specification of the customers

-

Structural steel (Q235B、Q355B、SPHT1、SPHT2)

Specification:Thickness: 0.8~1.8mm Width:1150-1580mm

Standard:GB/T 3274-2019、T/SSEA 0030-2019、T/SSEA 0031-2019、JIS G3132-2011

Application:Mainly used in agricultural machinery 、shelf、tubulation、door sheet、cabinet body etc.

-

Property Indexes

Q235B:Yield strength ³ 235MPa, tensile strength:370~500MPa, elongation rate ³ 23%

Q355B:Yield strength ³ 355MPa, tensile strength:470~630MPa, elongation rate ³ 15%

SPHT1:Tensile strength≥270MPa, elongation rate ³30%

SPHT2:Tensile strength≥340MPa, elongation rate ³25%

-

High Strength Low alloy steel Grade 55、Grade 65、Grade 70、Grade 80、Grade 100

Specification:Thickness:0.8~1.8mm;width:1150~1580mm

Standard:ASTM 1039,T/SSEA 0031-2019

Application:Mainly used in automobile structural parts,shelves and supports, truck bodies etc.

-

Property Indexes

Yield strength:400~700MPa, tensile strength:450~750MPa, Elongation meets corresponding standard requirements and the shape and surface quality of the product can reach a high level.

-

High Carbon Steel UTS-50JP

Specification:Thickness:0.8~1.8mm;width:1150~1570mm

Standard:Shagang enterprise standard

Application:Mainly used in tape、hairpin etc

-

Property Indexes

Satisfying composition,profile,specification of the customers.

-

Containers Steel SPA-H

Specification:Thickness:0.8~1.8mm;width:1150~1580mm

Standard:JIS G3125-2004、Shagang enterprise standard

Application:Containers

-

Property Indexes

Yield strength ³ 355MPa, tensile strength≥490Mpa,elongation rate ³ 22%。

-

Structural steel Q235B/Q345B

Specification:Thickness:0.8~1.8mm;width:1150~1580mm

Standard:GB/T 3274-2019、T/SSEA 0030-2019、T/SSEA 0031-2019、Shagang enterprise standard

Application:Mainly used in agricultural machinery ,shelf,tubulation,door sheet,cabinet body etc.

-

Property Indexes

Q235B:Yield strength ³ 235MPa, tensile strength:370~500MPa, elongation rate ³ 23%

Q345: Yield strength ³ 345MPa, tensile strength:470~630MPa, elongation rate ³ 15%.